The Future of Warfare: 3D Printing Drones on the Front Lines

As conflicts evolve and technology advances, the battlefield landscape is undergoing a transformative shift. U.S. soldiers may not only deploy drones but also manufacture them using innovative 3D printing technologies. This capability is becoming crucial for military effectiveness, particularly in fast-paced environments, such as those witnessed in Ukraine.

The current production capacity for drones by U.S. manufacturers pales in comparison to global leaders. While around 500 U.S. dronemakers produce approximately 100,000 units a year, the Chinese company DJI alone can manufacture millions. This disparity highlights an urgent need for the United States to enhance its drone production capabilities. Startups like Firestorm Labs are stepping in to bridge this gap with pioneering 3D printing solutions tailored for military use.

3D Printing Solutions for the Military

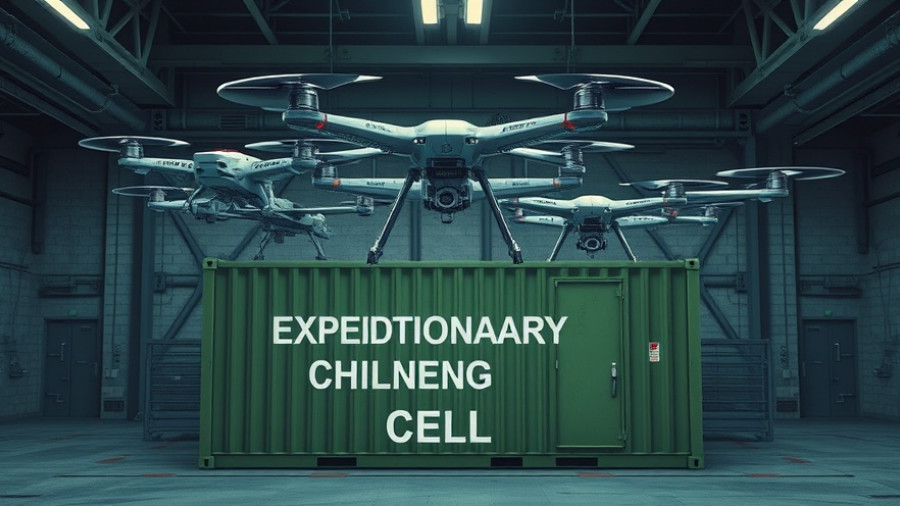

Firestorm Labs is developing mobile manufacturing systems that enable troops to manufacture drones right at the front lines. Their xCell expeditionary manufacturing system, housed within a shipping container, can produce a six-foot-long drone body in just 14 hours using industrial-grade 3D printers. According to Dan Magy, CEO of Firestorm, this technology addresses the logistical challenges of traditional drone production, making it feasible for soldiers to access needed equipment without depending on delayed supply chains.

This trend of 3D printing extends beyond production; it includes the idea of modular drones tailored to specific missions. The Army's initiatives to develop on-demand 3D printed drones have already shown promise. Recent tests have involved producing small drone units designed to detect threats that are invisible to conventional surveillance methods. These drones are not only cost-effective but allow for rapid adaptation to changing battlefield circumstances.

Implications for Business and Technology

For small and medium-sized business owners, these military advancements resonate beyond the defense sector. The ability to quickly produce tailored products could parallel shifts in various industries, from manufacturing to retail. The 3D printing technology enabling on-site production may inspire businesses to reconsider operational efficiency and responsiveness to market demands.

Additionally, embracing AI and similar technological innovations could lead to significant enhancements in service delivery and productivity. As military and commercial applications of 3D printing continue to evolve, businesses should look for ways to integrate these advancements to optimize their operations.

Call to Action: Embrace the Future of Production

As we witness the transformative potential of 3D printing in defense, it becomes imperative for business leaders to stay informed about these trends. Understanding how technologies like 3D printing can optimize production lines, reduce costs, and enhance customization will be vital in shaping future strategies. Take time to explore how similar innovations can be applied in your service industries, positioning your business for growth and adaptability in an ever-changing landscape.

Add Row

Add Row  Add

Add

Write A Comment